Penerangan

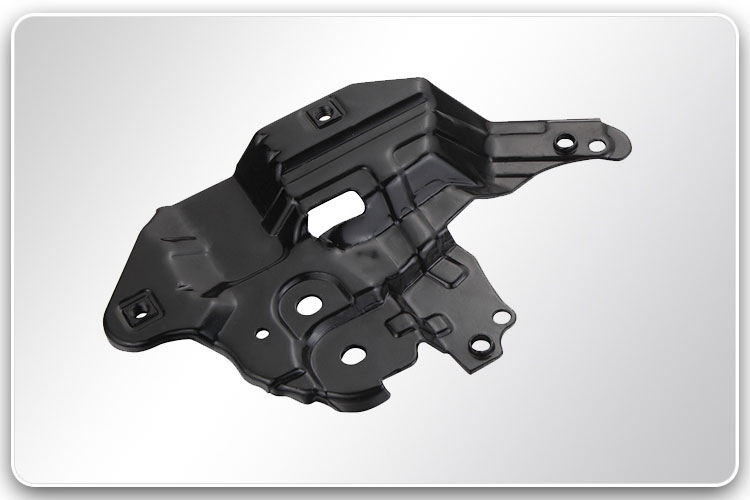

Stamping adalah proses meletakkan logam lembaran rata dalam bentuk orcoil kosong menjadi atekan setemdi mana alat danmatipermukaan membentuk logam menjadi bentuk jaring. Stamping merangkumi pelbagai proses pembuatan kepingan logam, sepertipunchingmenggunakan amesin tekan or tekan setem, mengosongkan, membongkok, membongkok, bebibir, dan melekat.

Stamping could be a single stage operation where every stroke of the press

produces the desired form on the sheet metal part, or could occur through a

series of stages. Progressive matis are commonly fed from a coil of steel, from coil

reel to a straightener to level the coil, and then into a feeder which advances

the material into the press and mati(s) at a predetermined feed length.

Depending on part complexity, the number of stations in the mati can be varied.

Stamping is usually done on cold metal sheets, whereas for progressive

stamping, coil steel is used.

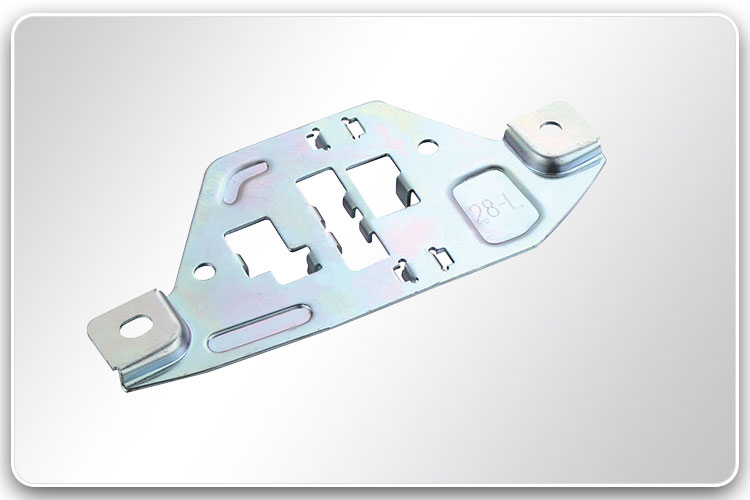

For product development, the forming mati is often developed first, using

laser cutting instead of blanking for trial runs, once the final product meets

the expectation, the blanking matis are developed.

In stamping, the stamping parts can become the final product after surface

treatment, mostly however, it is only used as a functional component for

product assembly.

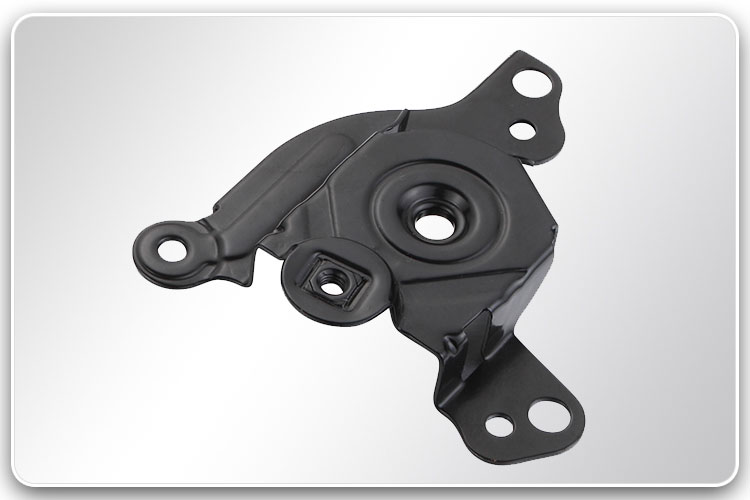

The normal surface treatment processes for stamping parts include

electrophoresis (KTL), powder coating, painting, and zinc plating. For all

surface treatment, we offer coating adhesion, thickness, and salt fog tests or,

other tests to be conducted upon request. Anodizing is available for aluminum

materials.

Technical Specifications

-Bahan

Mild steel, stainless steel, copper, brass, aluminum, and alloy steel.

-Kapasiti mesin

1,200 ton hydraulic press machine, 800 ton stamping machine, material thickness

can be from 0.2mm to 12mm.

Auwell mampu merancang dan mengembangkan alat yang diperlukan untuk proses stamping termasuk alat pengukur untuk pengeluaran besar-besaran QC. CMM tersedia untuk pemeriksaan dimensi sampel. Rawatan permukaan termasuk KTL, lapisan serbuk, lukisan, dan zinkplating. Dokumen PPAP disediakan atas permintaan.

Advantages

-Rich Experience

More than 20 years of experience in stamping products development and

production, especially to the European and North American markets, with solid understanding

of the material, technical and quality standards worldwide.

-Fast Turnaround

Secara amnya, kami memberikan sebut harga dalam masa 3 hari bekerja. Menggabungkan teknologi dan kemudahan pembuatan terkuat, Auwell dapat menyediakan prototaip cepat hanya dalam 2 minggu untuk projek sederhana.

-Penyedia Penyelesaian Komprehensif

Auwell provides comprehensive services for stamping projects starting from

designing, through prototyping, tooling/fixture development, sampling, mass

production, and to logistic and post-sale support.

-Rigid QC Policies

The most rigorous quality policy starts from material control, and is

followed through to final pre-shipment inspection. Bahan certificates

include the mill certificate, 3rd party chemical components, and mechanical

property reports, as well as RoHS and REACH reports upon request. Other reports

include dimensional reports, surface treatment thickness, and salt fog test reports,

etc. We structure our processes, creating Flow Charts and Control Plans before

production, making sure all QC processes are in accordance with ISO9001-2015

requirements and drawing specifications.

-Flexible Payment Term

Tooling payments need to be pre-paid. For mass production, we offer

flexible payment terms, reasonable credit terms will be given, the client only

pays when they are happy with the product they received. For long-term

projects, we offer call-off inventory services for fast delivery requirements.

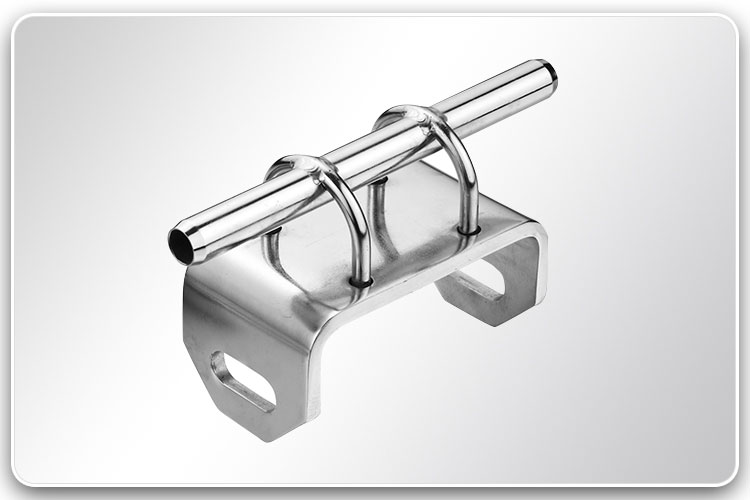

Applications

Stamping products have widely been used in almost all industrial sectors

including:

-Aeroangkasa

-Agriculture

-Peluru

-Major appliances

-Peralatan kecil

-Automotive

-Commercial

-Pembinaan

-Electronics

-Lengan api

-HVAC

-Lawn care and equipment

-Pencahayaan

-Lock hardware

-Marine

-Perubatan

-Paip

-Power storage

-Power tools

-Enjin kecil

Click following link for browsing of various stamping

products that Auwell has produced and supplied to our distinguished worldwide clients.

Please be advised, most of the products are for demonstration purpose only.

Bahagian Stamping

English

English  Español

Español  Português

Português  русский

русский  Français

Français  日本語

日本語  Deutsch

Deutsch  tiếng Việt

tiếng Việt  Italiano

Italiano  Nederlands

Nederlands  ภาษาไทย

ภาษาไทย  Polski

Polski  한국어

한국어  Svenska

Svenska  magyar

magyar  Malay

Malay  বাংলা ভাষার

বাংলা ভাষার  Dansk

Dansk  Suomi

Suomi  हिन्दी

हिन्दी  Pilipino

Pilipino  Türkçe

Türkçe  Gaeilge

Gaeilge  العربية

العربية  Indonesia

Indonesia  Norsk

Norsk  تمل

تمل  český

český  ελληνικά

ελληνικά  український

український  Javanese

Javanese  فارسی

فارسی  தமிழ்

தமிழ்  తెలుగు

తెలుగు  नेपाली

नेपाली  Burmese

Burmese  български

български  ລາວ

ລາວ  Latine

Latine  Қазақша

Қазақша  Euskal

Euskal  Azərbaycan

Azərbaycan  Slovenský jazyk

Slovenský jazyk  Македонски

Македонски  Lietuvos

Lietuvos  Eesti Keel

Eesti Keel  Română

Română  Slovenski

Slovenski  मराठी

मराठी  Srpski језик

Srpski језик